The Critical Importance of Keeping ESD Mats Spotless

By: Richard Rich

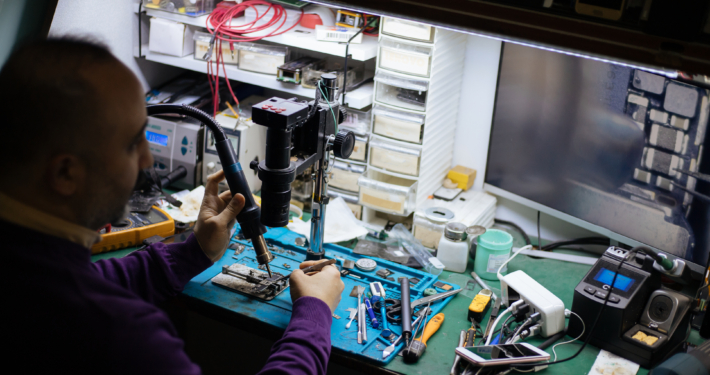

Electrostatic Discharge (ESD) mats serve as a fundamental tool in various industries, especially in electronics manufacturing and servicing, where they act as a safeguard against static discharge that can damage sensitive electronic components. Over time, however, these mats can become contaminated, potentially compromising their protective properties. Here, we delve deeper into the various types of contaminants and the ramifications of a soiled ESD mat.

Contaminants that Might Adhere to ESD Mats:

- Flux Residues: Commonly found in soldering processes, flux residues can degrade the mat’s surface over time, diminishing its ESD properties.

- Oils and Greases: These can be introduced from machinery or even from human contact. Excessive oils and greases can create insulating layers on the mat, rendering its ESD properties ineffective.

- Dust and Dirt: Accumulated dust can introduce unwanted insulating barriers on the mat’s surface. Furthermore, dust can sometimes contain minute metal particles, which could cause short circuits when they come in contact with electronic devices.

- Chemical Spills: Accidental spills from chemicals, solvents, or cleaning agents might react with the mat’s materials, leading to degradation.

- Adhesive Residues: Leftovers from tapes or labels can affect the mat’s conductivity and its overall ESD performance.

- Organic Compounds: Organic contaminants, such as food spills, can serve as breeding grounds for bacteria, mold, and mildew, potentially introducing more contaminants onto the mat over time.

The Implications of a Dirty ESD Mat:

- Loss of ESD Properties: The primary purpose of an ESD mat is to dissipate static charges, protecting electronic components. Contaminants can compromise this property, making the mat less effective or even entirely ineffective.

- Equipment Damage: With a compromised ESD mat, static electricity can discharge onto sensitive electronic components, causing irreparable damage.

- Decreased Lifespan of the Mat: Contaminants can degrade the mat materials, leading to a reduced operational lifespan and necessitating frequent replacements.

- Operational Inefficiency: In a setting where precise electronic assembly or repair is undertaken, a dirty mat can introduce contaminants into the equipment, causing malfunctions and necessitating rework.

- Health and Safety Concerns: Certain residues or spills can pose direct health risks to workers or even become a fire hazard in specific scenarios.

Final Thoughts:

Understanding the profound importance of ESD mat cleanliness isn’t merely about hygiene—it’s a matter that intertwines operational efficiency, cost savings, and safety. The detrimental effects of a dirty mat extend well beyond appearance. As such, regular cleaning using appropriate cleaning agents like ESD Mat Cleaners becomes not just a recommended practice but a critical necessity.

I.C. Workstation Cleaner is the multi-purpose, no residue solution to cleaning mats and workstations in cleanroom or sterile environments. Formulated safe-for-use, I.C. Workstation Cleaner lacks the ingredients that would hinder its compatibility with equipment and surfaces. Safely clean and restore your work surface with a mildly cationic cleaner. Achieving the complete cleansing of static or filth-related contamination and leaving a streak-free shine to protect and refurbish your mats.