A Guide to Maintaining a Static-Free Environment in 2024 with R&R Lotion Products

By: Richard Rich

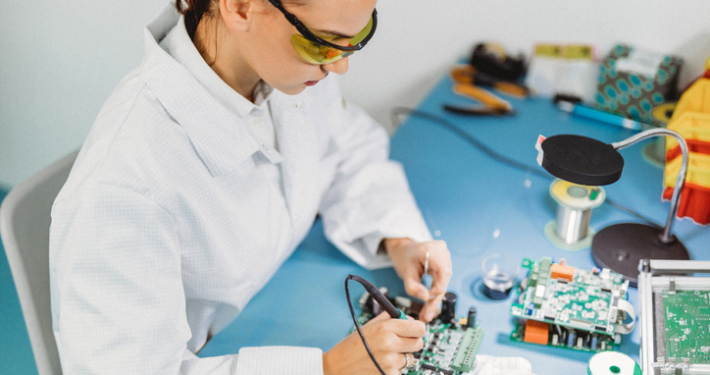

As we move into 2024, the challenge of maintaining a static-free environment in electronic manufacturing and repair remains crucial. Static electricity, a subtle yet significant threat, can lead to the damage of sensitive components and economic losses. To address this, R&R Lotion’s static control products emerge as a key solution. This guide provides an in-depth look at best practices for using these products to ensure a safe and efficient workspace.

Understanding Static Electricity Risks in Modern Electronics

The generation of static electricity in the workplace, a common occurrence, can have disastrous effects on electronic components. Factors like advanced technology materials, flooring types, and even the clothing of technicians contribute to static build-up, making an understanding of these elements more important than ever.

Key R&R Lotion Products for 2024 Static Control

R&R Lotion provides a comprehensive range of products designed to combat static risks, essential for the evolving needs of the electronic industry in 2024:

- ESD Mat Workstation Cleaners: Essential for maintaining static-dissipative surfaces at workstations.

- ESD Safe Bottles: Specially designed for the safe dispensing of solvents and flux during electronic assembly and rework.

- Non-Contaminating Hand Lotions: These lotions are formulated to moisturize without leaving conductive residues, crucial in handling sensitive electronics.

- Topical Antistatic Coating: This product offers additional protection by directly reducing static charges on various surfaces.

- Static Shielding Bags: These are indispensable for the safe storage and transport of electronic components, protecting them from ESD damage.

- ESD Laminating Sheets: Ideal for preserving important documents and labels in ESD-sensitive environments, these sheets ensure that paper products don’t contribute to static build-up.

Implementing a Static Control Protocol

Effective use of R&R Lotion products involves:

- Training and Awareness: Continuous education about ESD risks and proper product usage.

- Routine Cleaning: Regular use of ESD mat cleaners to maintain a static-free environment.

- Proper Dispensing Practices: Ensuring ESD safe bottles are used for all liquid dispensing.

- Regular Application of ESD Safe Lotions: Encouraging technicians to use these lotions, especially after hand-washing.

Monitoring and Advancing Static Control Practices

- Regular Testing: Using advanced ESD testing equipment for effective measure.

- Feedback and Adaptation: Open feedback channels for insights on product usability and effectiveness.

- Staying Current: Keeping up with the latest static control technologies and integrating new practices as necessary.

In 2024, a static-free environment remains essential for the integrity of electronic products. By leveraging R&R Lotion’s products and these updated best practices, businesses can minimize ESD risks, ensuring a safe and productive environment for handling sensitive electronics.